Product Case Studies

Discover how our innovative solutions solve real-world challenges for our clients.

Our Solutions in Action

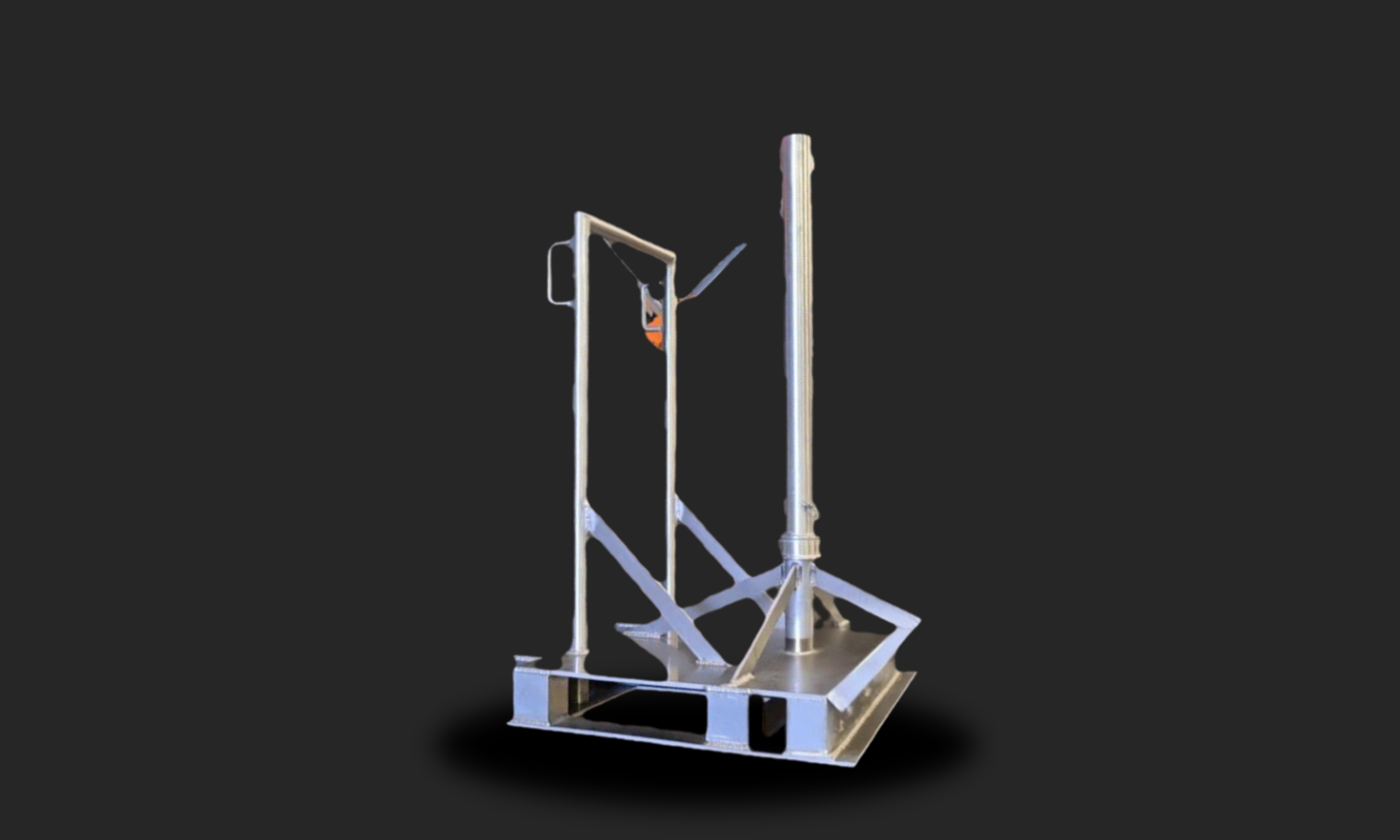

A 5S storage case study delivered by Techmine, addressing disorganised and unsafe storage of lifting equipment through engineered container solutions that improve safety, accessibility, asset protection, and site efficiency. Detailed outcomes are available in the supporting case study below .

A case study demonstrating Techmine’s adjustable workbench solution, engineered to improve ergonomics, manual handling safety, and task efficiency through height-adjustable, high load-rated designs tailored to site requirements. Detailed outcomes are available in the supporting case study below.

A case study detailing Techmine’s Zero Gravity Arm solution, designed to reduce operator fatigue and manual handling risk by enabling controlled, single-handed operation of water cannons and tools in confined and high-risk environments. Detailed outcomes are available in the supporting case study below.

A case study outlining Techmine’s Lancing Rod solution, engineered to improve operator safety, control, and reach during high-risk maintenance tasks by reducing manual handling strain and exposure to hazardous conditions. Detailed outcomes are available in the supporting case study below.

A case study detailing Techmine’s Turnover Bar solution, engineered to safely rotate and handle heavy components while reducing manual handling risk, strain injuries, and uncontrolled movement during maintenance and fabrication tasks. Detailed outcomes are available in the supporting case study below.

A case study presenting Techmine’s Ergonomic Fuel Handle solution, developed to reduce operator fatigue, improve grip and control, and minimise repetitive strain during fuel handling tasks.Detailed outcomes are available in the supporting case study below.