Australian Made Conveyor Belt Lifters & Overland Conveyor Maintenance Equipment

TECHMINE SOLUTIONS

WORK SMARTER NOT HARDER

DELIVERING TRUST

About Company

Australian Made Conveyor Belt Lifters & Overland Conveyor Maintenance Equipment

Techmine Solutions designs and manufactures Australian-made conveyor belt lifters and overland conveyor maintenance equipment engineered for heavy-duty mining applications. Our aluminium lifting systems support belt widths from 900 mm to 3000 mm, enabling safer and more efficient idler change-outs, belt inspections, and shutdown maintenance across bulk handling operations. Built to withstand harsh Pilbara and global mining environments, Techmine belt lifting systems are developed in line with relevant Australian and Global Standards and trusted by maintenance teams seeking reliable conveyor lifting solutions.

Conveyor Maintenance Equipment Designed for Mining Operations

Techmine specialises in engineered conveyor maintenance solutions developed to improve safety, reduce manual handling, and increase productivity during shutdowns and routine maintenance. Our equipment is designed in collaboration with site maintenance teams and continuously refined through real-world deployment across overland and plant conveyor systems.

0

Years Of Combined Experience Across Mining

0

Reduction in Lost Time Injuries (LTI) after implementation of Techmine belt lifters

0

Beams delivered

0

Failures in field application

Mechanical Conveyor Belt Lifters

Hydraulic Conveyor Belt Lifting Systems

Conveyor Lifting Beams & Spreader Beams

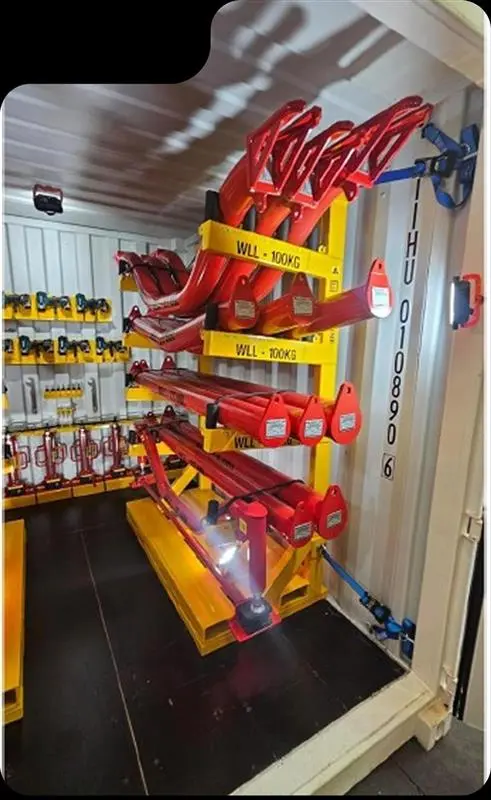

5S Conveyor Maintenance Containers

Engineered for Safety, Performance and Compliance

Every Techmine product is developed with a strong engineering focus, incorporating load-rated designs, practical deployment methods, and operational feedback from maintenance teams. Our conveyor lifting equipment is engineered with consideration to Australian Standards and designed to reduce manual handling risks while improving maintenance efficiency.

Techmine Products

Proven in Real Mining Operations

• Used during conveyor shutdowns across Pilbara iron ore operations • Supporting maintenance crews during idler change-outs and belt inspections • Designed with feedback from field technicians and maintenance planners

5S Container

Fully engineered, mine-ready storage solution designed to keep all conveyor belt lifting equipment organised, protected, and instantly accessible.

Read more →

Mechanical Belt Lifter

Lightweight aluminium and heavy-duty mechanical belt lifters designed for overland conveyors and fixed plant maintenance, 1T 2T 3T Working Load Limit (WLL).

Read more →

Conveyor Lifting Beams and Spreader Beams

Engineered lifting flat beams, trough beams, V-beams and certified rigging equipment developed to stabilise belt lifting operations and improve safety.

Read more →

Mechanical telescopes

Primary and secondary belt cleaners to remove carryback and ensure a clean, efficient conveyor system.

Read more →

Wing Lifter

Effective skirting and sealing systems to contain material, reduce spillage, and control dust.

Read more →

Hydraulic Conveyor Belt Lifting Systems

High-capacity hydraulic lifting systems engineered for wide belts and heavy-duty and customized conveyor structures, 1T or 2T Working Load Limits.

Read more →Collaborations

Delivering Trust Globally to our Partners and Clients

Global Scale Presence

Trusted by Companies Around the World

0

Countries having active global scale services

0

Companies with Techmine gear

0

Years field-tested

Techmine Aftercare Services

Service For Our Products

An industrial company specializing in conveyor belt manufacturing provides end‑to‑end solutions that keep material handling operations efficient, safe, and reliable. We offers annual maintenance, and rapid repair services to minimize downtime, extend equipment life, and ensure that production lines run smoothly around the clock.

Techmine Featured Projects

Project Case Study

Techmine doesn’t stop at just providing the tools. They also prioritize user knowledge by offering training programs on the safe and effective operation of their equipment.

In addition to product delivery, Techmine provides ongoing servicing, maintenance support, and equipment upgrades to ensure long-term performance and reliability in the field.

5S Container

Lifting equipment was disorganized and often lost or damaged. A secure, labeled 5S-based storage container was implemented, improving accountability, maintenance, and reducing theft through structured, lockable, and auditable organization.

Read more →

Adjustable Workbench

Traditional benches lacked height adjustability, mobility, and ergonomics, causing fatigue and inefficiency. A new adjustable bench with telescopic supports, hex-drive lift system, and durable design improved safety, flexibility, and workflow efficiency.

Read more →

Zero Gravity Arm

Manual washdowns caused fatigue and safety risks due to heavy cannons and poor ergonomics. A lightweight, adjustable Zero Gravity Arm improved reach, reduced strain, enabled one-hand operation, and enhanced efficiency across access points.

Read more →

Ergonomic Fuel Handles

Modified nozzle design and butterfly wings on the nozzle for Ergonomics

Read more →